Revisions and the edition of this document

The current and most recently published edition of this document is available at www.milleteknik.com.

The validity of this document can not be guaranteed, as new editions are published without prior notice.

Instructions for use in Swedish in original.[1].

Instructions for use, technical data and translations thereof may contain errors. It is always the responsibility of the installer to install the product in a safe manner.

Symbols

Symbols | Denomination | Explanation |

|---|---|---|

| Warning | Risk of electric shock, improper installation or hot surfaces. Appears in some manuals |

| Note | Used for supplementary information that clarifies the text. |

| Caution/Important | Indicates the risk of equipment damage or malfunction. Also used for information that is important but not security-related |

| Tips | Displays practical advice or shortcuts for installation, operation, or service. |

| CE marking | The product complies with applicable EU directives and harmonised standards. |

| Read the manual | Please read manual before installation and service. |

| Do not dispose of in household waste | The product is covered by the WEEE Directive and must not be disposed of with household waste, it must be recycled and delivered to a recycling centre. |

Recycling | Packaging, products and other materials that do not contain electronics must be recycled in accordance with local environmental regulations. |

Variant overview NOVA

Product name | Certified name | Motherboard: PRO1 | Motherboard PRO2: | Motherboard PRO2 v3 | Motherboard: PRO3 |

|---|---|---|---|---|---|

NOVA 12V 10A FLX S | 12 V meets the requirements but is not certified. | - | - | - | x |

NOVA 12V 10A FLX M | - | - | - | x | |

NOVA 12V 10A FLX L | - | - | - | x | |

NOVA 24V 5A FLX S | NOVA 25 50-FLX-S | X | X | - | X |

NOVA 24V 10A FLX S | NOVA 25 100-FLX-S | X | X | - | X |

NOVA 24V 5A FLX M | NOVA 25 50-FLX-M | X | X | - | X |

NOVA 24V 10A FLX M | NOVA 25 100-FLX-M | X | X | - | X |

NOVA 24V 15A FLX M | NOVA 25 150-FLX-M | X | X | X | - |

NOVA 24V 25A FLX M | NOVA 25 250-FLX-M | X | X | X | - |

NOVA 24V 5A FLX L | NOVA 25 50-FLX-L | X | X | - | X |

NOVA 24V 10A FLX L | NOVA 25 100-FLX-L | X | X | - | X |

NOVA 24V 15A FLX L | NOVA 25 150-FLX-L | X | X | X | - |

NOVA 24V 25A FLX L | NOVA 27 250-FLX-L | X | X | X | - |

Read this first!

Electronics, regardless of enclosure, are intended for use in a controlled indoor environment. Mains voltage should be disconnected during installation.

It is the installer's responsibility that the system is suitable for its intended use. Only authorized persons should install and maintain the system.

All information subject to change.

About glass tube fuses on certified devices

There are glass tube fuses on the circuit board's load outputs, these have a tripping time of approx. 150 ms. In the event that a glass tube fuse trips on ONE load output, the voltage on ALL load outputs drops to 0 V for 150 ms.

The installer is responsible for ensuring that there is an energy buffer of at least 150 ms in systems that the battery backup supplies power to or accepts a power failure of 150 ms.

Installation — general information

Installation shall be carried out by a competent electrician in accordance with the applicable national electrical installation rules.

The product is of protection class I and must be connected to a grounded 230 V AC circuit.

A main switch according to IEC 60947-1 shall be provided in the fixed installation. The switch should be easily accessible and clearly marked with its function.

The area of the supply cable shall be at least 1,0 mm² and fitted with a fuse T 2,5 A (slow-blown) or equivalent.

AC and low voltage cables must not be pulled together. Keep separate cable chutes or bundles

Check that protective earth (PE) is properly connected before turning on voltage.

Ensure free air circulation around the enclosure at least 100 mm, unless otherwise specified. Ventilation openings must not be covered.

The product is intended for indoor installation in normal environment (pollution number 2 and indoor class 1).

These general requirements apply to all Milleteknik products with 230 V mains connection.

Requirements for main switch, fuse and cable area

In order to comply with applicable electrical safety requirements, the installation shall be equipped with a main switch according to IEC 60947-1.

Component | Requirements |

|---|---|

Main switch | A main switch according to IEC 60947-1 shall be included in the installation and be easily accessible. Separated phase (F) and neutral (N) |

Fuse | The supply circuit shall be protected by a fuse or automatic fuse with rated current according to the product specification (normally T 2,5 A slow-blown or equivalent). Refer to the device's nameplate. |

Fuses | Approved type according to IEC 60127. |

Cross-sectional area (230 V) | At least 1,0 mm2 |

Cable length | In the case of longer wiring, voltage drops should be taken into account so that the operating voltage does not fall below 230 V ± 10% at the unit. |

Strain relief | All cables must be properly secured and strain relief checked before energizing the unit. |

These requirements apply to all Milleteknik products with 230 V mains connection.

The table below shows recommended cable area for low current installations at different voltages, current strengths and cable lengths. Values are based on copper cable and a maximum voltage drop of approximately 3% to ensure operational reliability.

V | Current strength (A) | Cable length 10 meters | Cable length 30 meters | Cable length 60 meters | Cable length 100 meters |

|---|---|---|---|---|---|

24V | 1 A | 0,75 mm2 | 0,75 mm2 | 1,5 mm2 | 1,5 mm2 |

24V | 3A | 0,75 mm2 | 0,75 mm2 | 1,5 mm2 | 2,5 mm2 |

24V | 5A | 0,75 mm2 | 1,5 mm2 | 2,5 mm2 | 4 mm2 |

24V | 10A | 1,5 mm2 | 2,5 mm2 | 6 mm2 | -* |

24V | 15A | 1,5 mm2 | 4 mm2 | -* | -* |

24V | 25A | 2,5 mm2 | 6 mm2 | -* | -* |

24V | 40A | 4,0 mm2 | -* | -* | -* |

* Cable area would exceed connector terminal dimensions therefore it is not possible to use cable larger than 6 mm! 2 | |||||

Component overviews

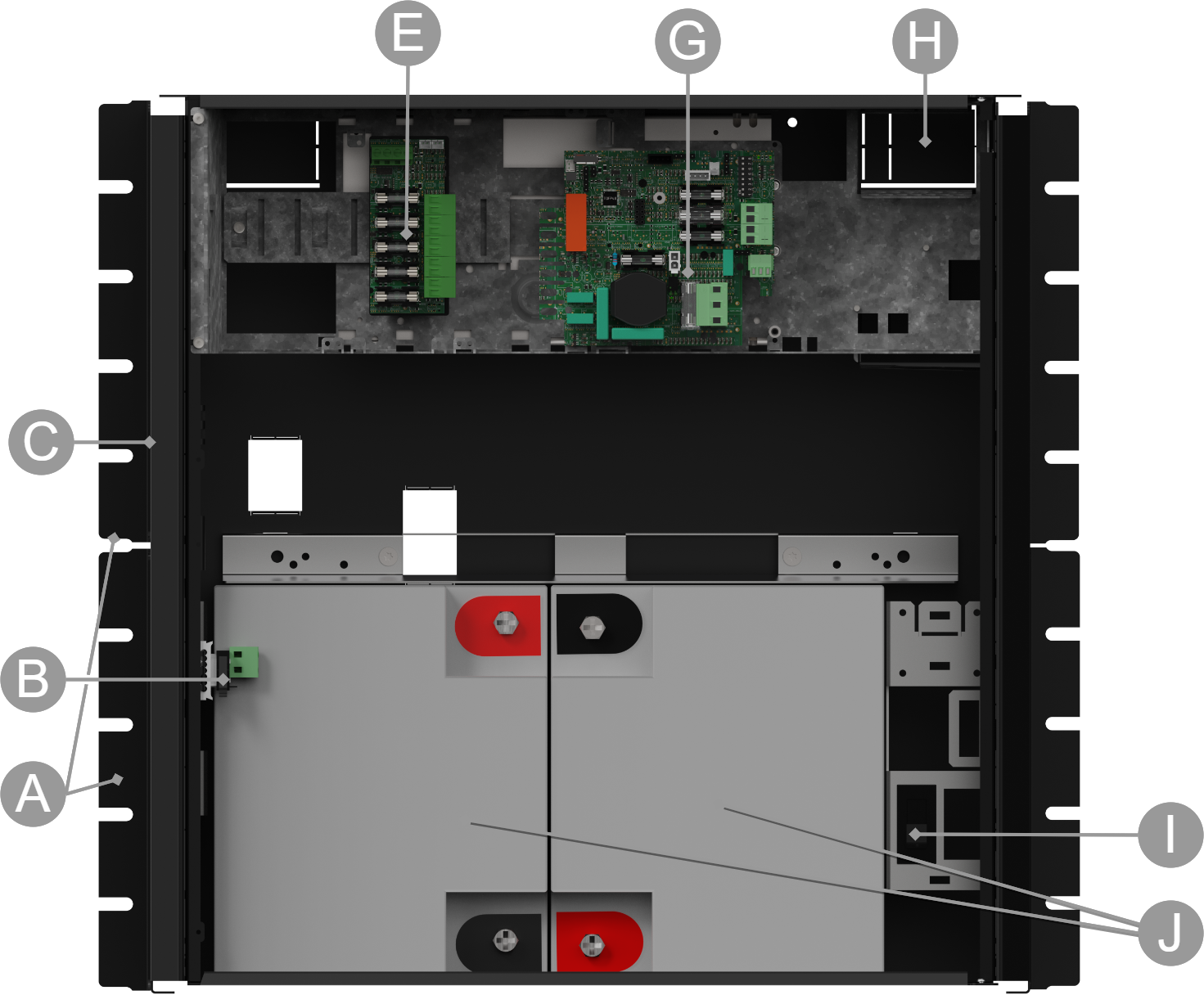

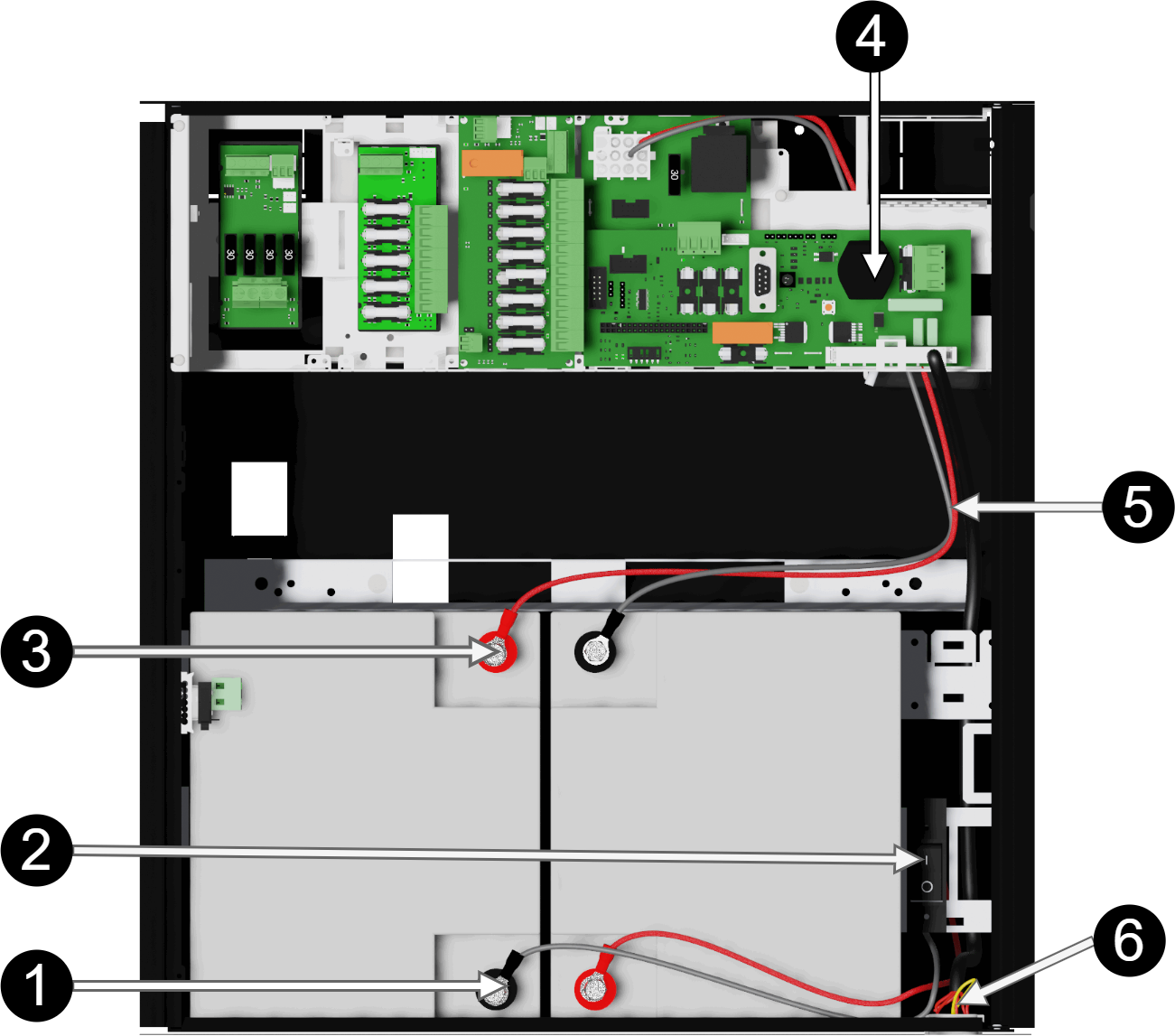

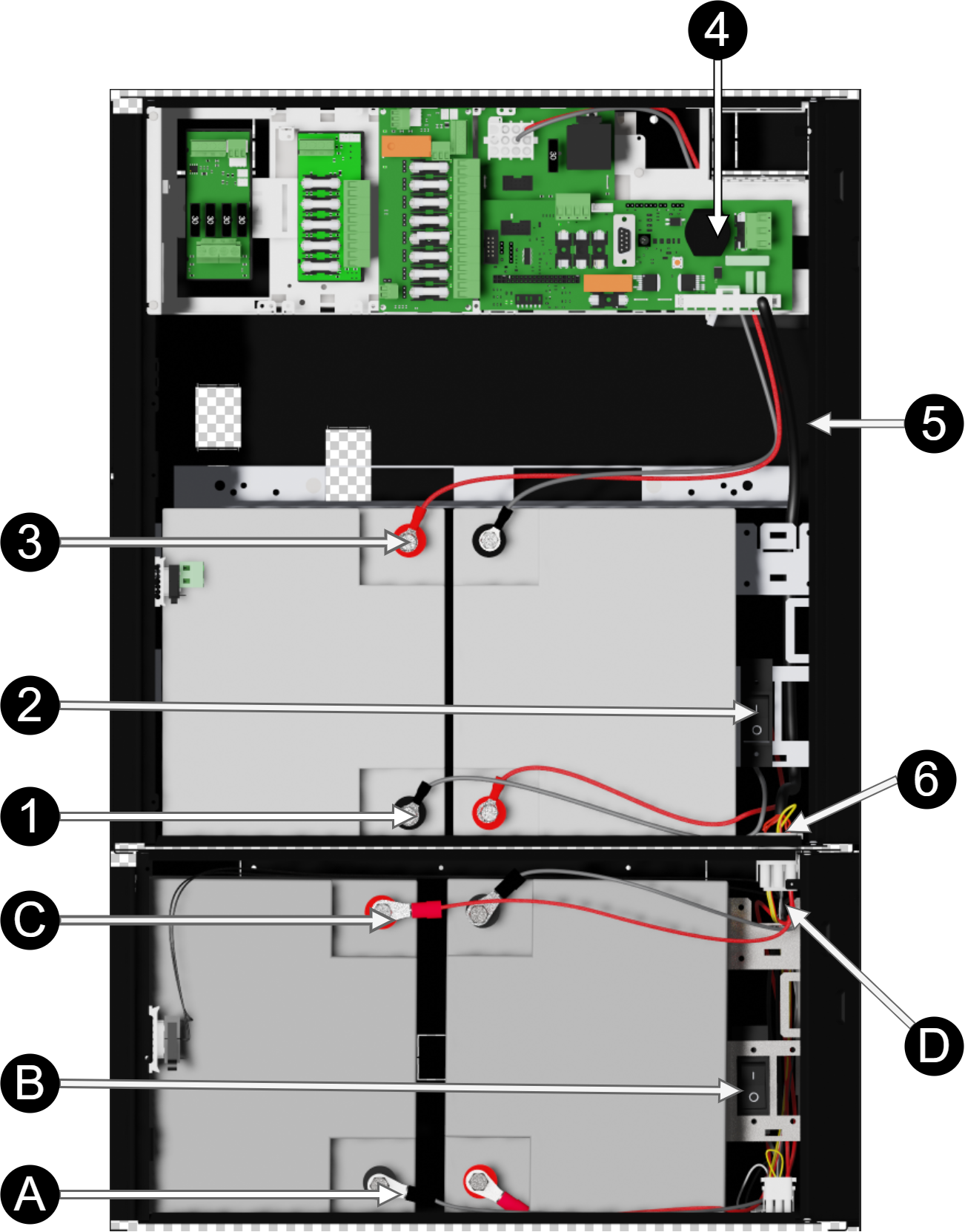

Component overviewNOVA FLX L

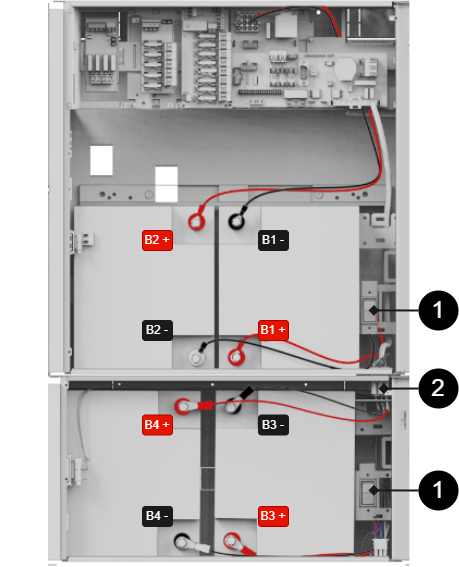

Batteries should be placed as in the picture.

Letter | Explanation |

|---|---|

A | Bracket, reversible for wall mounting or 19 "rack. |

B | Tamper switch. If alarm class 3 (SSF) is to be met, the tamper contact must be on the wall. |

C | Cabinet in powder-coated sheet metal. |

E | Space for mounting optional cards (not included). |

G | Motherboard, (varies with configuration). |

H | Cable entries. |

I | Battery fuse. |

J | Space for batteries. |

Enclosures

Console

The supplied brackets can be attached in two ways: When mounting on a wall, the brackets must sit backwards, against the wall. When mounting in a 19" rack, the bracket must sit at the front of the unit.

Letter | Explanation |

|---|---|

A | Console is pushed in from the bottom up. Slide the top bracket in first. |

B | Clip clicks in when bracket is pushed in correctly. |

Important

If alarm class 3 (SSF) is to be met, the cabinet and tamper switch must be mounted on the wall. Optional, Cabinet tamper M/L to put a tamper switch on the wall is available.

Mounting

Use the appropriate screw for mounting on a wall or in a 19" rack. Screws for mounting on a wall or in a rack are not included.

Mounting - wall mounting

The products shall be mounted on a stable wall or mounting plate with sufficient bearing capacity for the weight of the enclosure, including batteries.

The enclosure is mounted vertically.

Use four screws with a diameter of 4—5 mm, depending on the substrate.

Recommended distance between screw head and wall should be 1.5-2 mm.

For mounting on drywall, wall anchors or expanders should be used.

When mounting on concrete or brick, dowels or equivalent fastening are used.

For good ventilation, at least 100 mm of free space should be provided above and on the sides of the enclosure.

The unit should be mounted at a comfortable working height, normally between 1.4 and 1.8 m above the floor.

Avoid placement in direct sunlight, near heat sources, or in environments with high humidity or dust.

For outdoor use, only enclosures with the specified IP class for outdoor use shall be used.

Installation shall be carried out in accordance with the applicable installation rules and by a competent installer.

Batteries - placement and connection

Connecting batteries in FLX M

Note that cards (4) differ from different configurations.

No | Explanation |

|---|---|

1 | Minus coil for battery cable from 4. |

2 | Fuse. |

3 | Plus terminal for battery cable from 4. |

4 | Motherboard, varies with configuration. |

5 | Battery cables are located on the system board. |

6 | Connection for connection of battery box. |

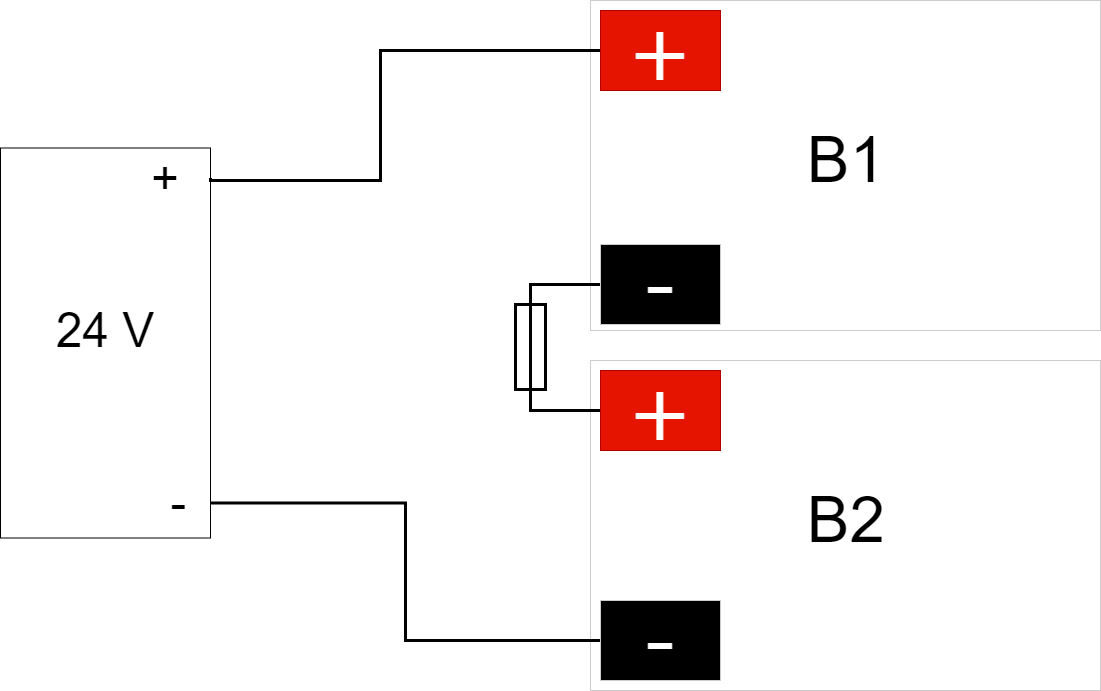

Connection of batteries in FLX S, FLX M and FLX L

Battery wiring is mounted on the circuit board upon delivery. Pictures below only show how to connect wiring.

Place the batteries in the cabinet with the battery terminals facing outwards.

Connect the battery cable. Red cable on + and black cable on -.

If possible, disconnect mains voltage when replacing the battery.

Connect the terminals correctly so that you do not damage the equipment.

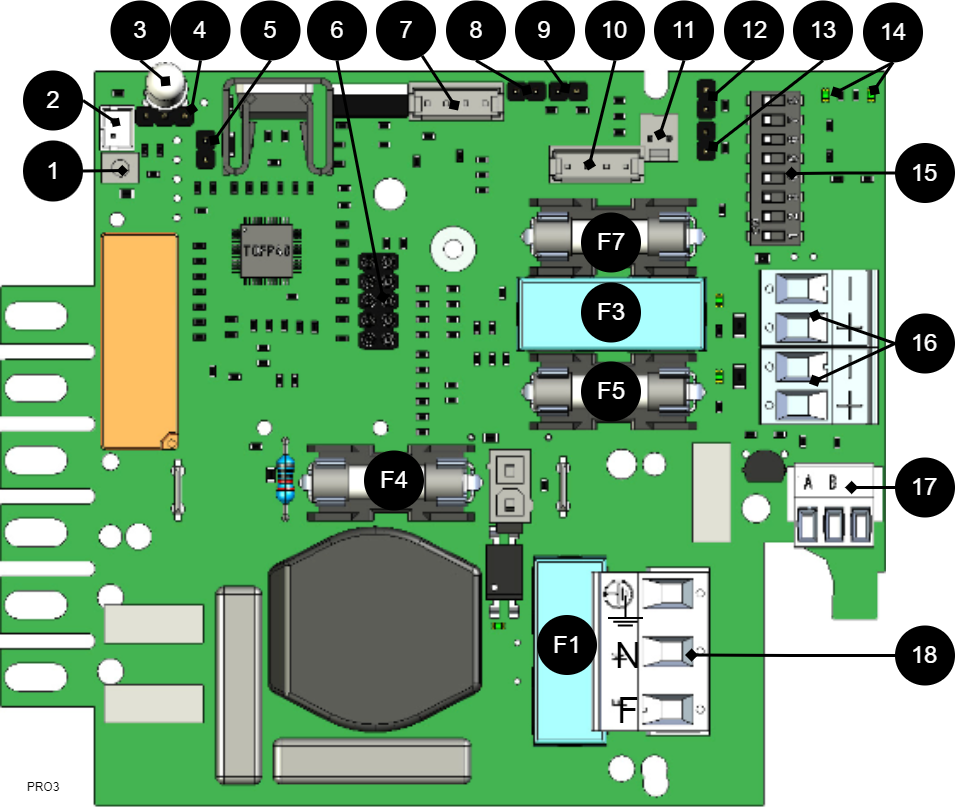

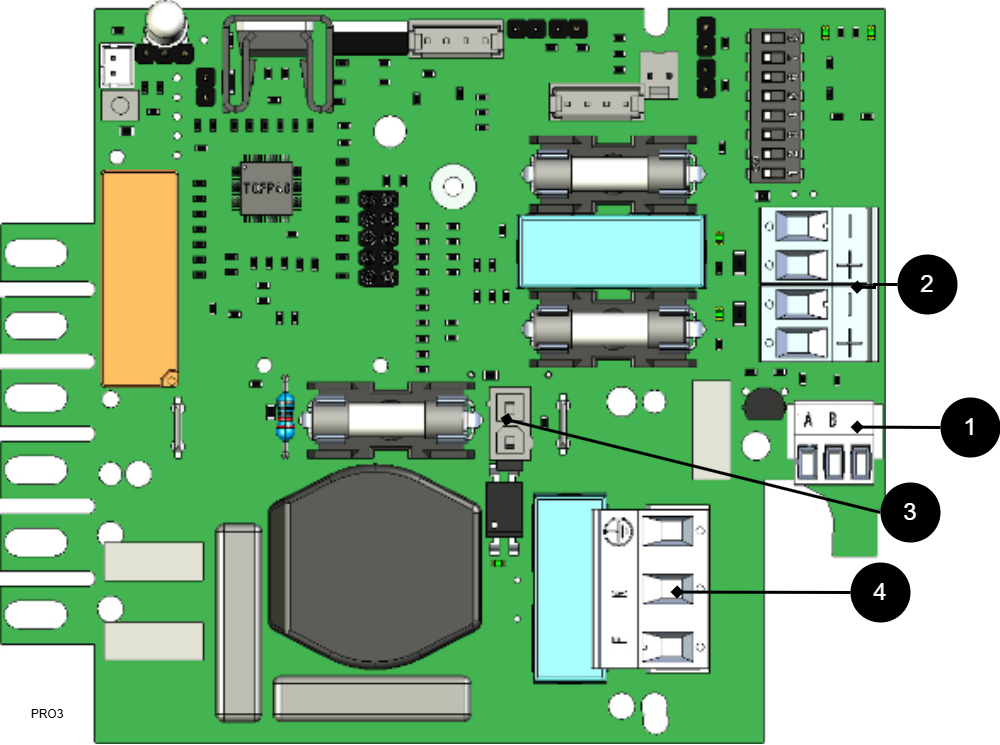

PRO3 motherboard

Motherboard - description

The motherboard controls the device and distributes power. See technical data for more information.

No . | On circuit board | Explanation |

|---|---|---|

1 | J24 | Control to power supplies. Internal use. |

2 | J5 | 1=Oprio 2=external alarm. |

3 | D9 | LED. |

4 | JU1 | For external LED in door. |

5 | J11 | Reset jumper, used when changing batteries. |

6 | JU6 | Connection for relay cards or communication cards or for updating firmware. Only one card or contact at a time can fit. |

7 | J29 | Connection to fan. |

8 | J101 | Connection to tamper contact. |

9 | J17 | Connection to tamper switch from battery box. |

10 | J35 | Not used. |

11 | J14 | Alarm input from external battery fuse, from battery box. |

12 and 13 | J10 and J100 | Alarm from external option card. |

14 | D18, D19 | LEDs show the status of communication (RS-485). |

15 | S3 | Dip switch |

16 | P2:1-4 | Load outputs |

17 | P3:1-3 | Communication connection, RS-485. |

18 | P1:1-3 | Connection to the mains. |

Fuses

Fuse | Type | Explanation |

|---|---|---|

F1 | T2.5A | Mains fuse |

F3 | T16A | Load fuse 1 - (for P2:2) |

F4 | T16A | Battery fuse |

F5 | T3A-T10A* | Load fuse 1+ (for P2: 1) |

F7 | T3A-T10A* | Load fuse 2 + (for P2:3) |

*The size of the fuse depends on the battery backup (rated) power outlet (A) . | ||

Warning for replacing fuses (current strength, A)

There is a risk of damage if the fuse is changed to a larger one than what the unit is delivered with. The function of the fuse is to protect the connected load and cables against damage and fire. It is not possible to change the fuse to a larger one to increase the power output.

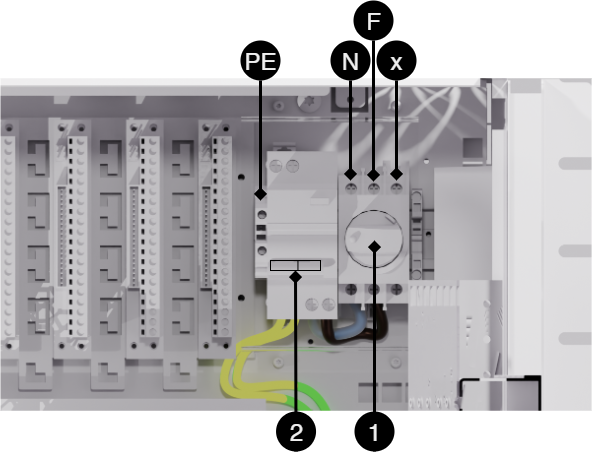

[sv] Anslut elnät

[sv] För in elnätskablage genom kabelgenomföringar på ovansidan skåpet.

[sv] Beteckning | [sv] Förklaring |

|---|---|

1 | [sv] Vred för nätspänning. |

2 | [sv] Personskydd / jordfelsbrytare. |

[sv] PE | [sv] Jord. |

N | [sv] Nolla. |

F | [sv] Fas. |

x | [sv] Används ej. |

Connect load

Max current

The maximum current must not be exceeded. Max current is indicated on nameplate on the device.

Load outputs when SSF certified

In order for certificates to be maintained, only one load output must be used.

If there are one or more connection cards (to increase the number of load outputs), load must be connected there and not on the main board.

On circuit boards | Explanation |

|---|---|

P2: 1 | Connection for load 1 +. |

P2: 2 | Hookup for load 1 -. |

P2: 3 | Connection for load 2 + |

P2: 4 | Connection for load 2 - |

Dip switch 1-8

Dip-Switch has several different modes:

Dip switch | In mains operation or in battery operation |

|---|---|

1 | Address for external communication. |

2 | Address for external communication |

3 | Address for external communication |

4 | Address for external communication |

5 | Sets alarm for mains failure delay |

6 | Sets alarm for mains failure delay |

7 | Sets alarm limit for low battery voltage in battery operation. |

8 | Turns off or turns on LED indication, for everything except alarm in case of triggered tamper contact which is always indicated regardless of dip-switch position. |

8 in sequence | Perform battery tests. |

Address setting for external communication (Dip switch 1-4)

Dip-Switch S1: 1-4 sets addressing.

Dip: 1 | Dip: 2 | Dip: 3 | Dip:4 | |

|---|---|---|---|---|

Adress 1 | ON | OFF | OFF | OFF |

Adress 2 | OFF | ON | OFF | OFF |

Adress 3 | ON | ON | OFF | OFF |

Adress 4 | OFF | OFF | ON | OFF |

Adress 5 | ON | OFF | ON | OFF |

Adress 6 | OFF | ON | ON | OFF |

Adress 7 | ON | ON | ON | OFF |

Adress 8 | OFF | OFF | OFF | ON |

Adress 9 | ON | OFF | OFF | ON |

Adress 10 | OFF | ON | OFF | ON |

Adress 11 | ON | ON | OFF | ON |

Adress 12 | OFF | OFF | ON | ON |

Adress 13 | ON | OFF | ON | ON |

Adress 14 | OFF | ON | ON | ON |

Adress 15 | ON | ON | ON | ON |

Mains failure delay (dip 5-6)

It is possible to change the time for when the alarm for a power outage should be given. Use the matrix to set the alarm.

Alarms for mains failure are given after: | Dip 5 | Dip 6 |

|---|---|---|

3 seconds | OFF | OFF |

30 minutes | ON | OFF |

60 minutes | OFF | ON |

240 minutes (4 hours) | ON | ON |

Low battery voltage (dip 7)

Dip: 7 has the same function regardless of whether the unit is in mains or battery operation or whether the tamper switch is held down.

Alarm for low battery voltage is given when | Dip 7 |

|---|---|

22,8 V* | ON |

24 V | OFF |

*25% of battery capacity remains. | |

LED (dip 8)

LED/battery-test always lights up when the door is open.

Dip-switch 8=ON turns off the LED.

Dip-switch 8=OFF turns on the LED.

Battery test (dip 8)

To do a battery test, dip 8 needs to change position and five seconds need to pass before the test is initiated.

If dip 8 in original position is on OFF then switch dip 8 to: ON (wait 5 seconds) and then switch back to OFF.

If dip 8 in original position is on ON then switch dip 8 to: OFF (wait 5 seconds) and then switch back to ON.

This activates the battery test after 3-8 seconds. The battery test lasts for about 6 seconds and then the LED flashes yellow quickly. Aged battery alarms may be indicated while the battery test is being performed.

Only reset dip 8 when the test is complete.

Reboot to confirm changes in address, battery and alarm settings to parent system

After the dip-switch has been set for various parameters, the device's software needs to be restarted. This is for the new settings to be stored and take effect.

Important

Rebooting according to this procedure does not interrupt the output voltage.

Restarting the device software is done by jumpering J11 (PRO3)

Important

Reboot must be done every time a change is made to the device.

NEO cannot be connected to communication/UC.

Reset after battery replacement -PRO3

After battery replacement, the device needs to measure the capacity of new batteries and clear previously set battery capacity. All alarms are cleared from the units memory, statistics remains and can not be cleared.

Insert jumper on J11 and remove jumper on J11

After doing step, the battery capacity is cleared in the units memory and is ready to read the new battery capacity.

This procedure needs to be done each time the batteries are replaced or when connecting a battery box.

Note on test of batteries

At start-up, it takes 72 hours before the system performs battery tests. This is to ensure fully charged batteries and to collect averages / history for at least 72 hours. Thereafter, every four hours, a qualified cell sample of the batteries is performed.

Note on start-up with short-circuited batteries

Peak current at start-up with short-circuited batteries: Up to 30 A p-p for 200 ms. Always follow the start-up procedure.

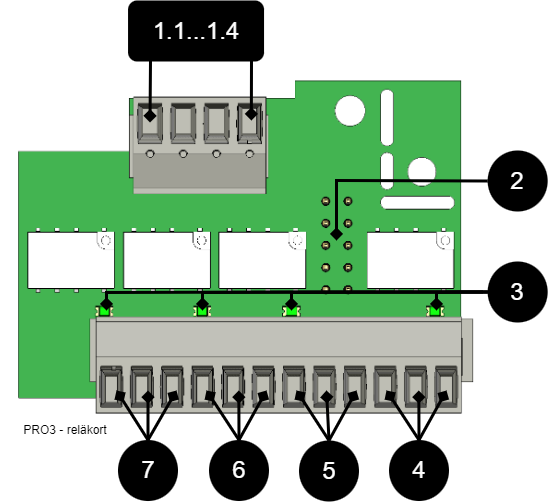

Card Description - Relay Card NOVA Series (PRO3)

Relay card - description, connections and alarm outputs.

All fault arm relays must be in the drawn state. Check that there is a gap between CO and NC. Put the measuring instrument on continuity measurement and test closure. This should then indicate a short circuit.

All relay outputs are normally live and give an alarm in the event of no voltage.

|

No . | Terminal no. | The relay is normally energized. | Alarm type / explanation |

|---|---|---|---|

1.1...1.4 | P4:1 | - | GND, protective earth |

P4:2 | - | RX | |

P4:3 | - | TX | |

P4:4 | - | +5V | |

2 | JU5 | - | Connection to motherboard. |

3 | D2-D6 | - | Indicator diode, lit green when OK. |

4 | P5:10-12 | NC, COM, NO | Alarm from tamper switch, (optional for NEO and EN54). |

5 | P5:7-9 | NC, COM, NO | Low system voltage. |

6 | P5:4-6 | NC, COM, NO | Alarm for fuse failure, charger failure overvoltage, charger failure undervoltage, battery not connected, low battery voltage in case of mains failure and aged battery*. *NOVA only. |

7 | P5:1-3 | NC, COM, NO | Mains failure alarm. |

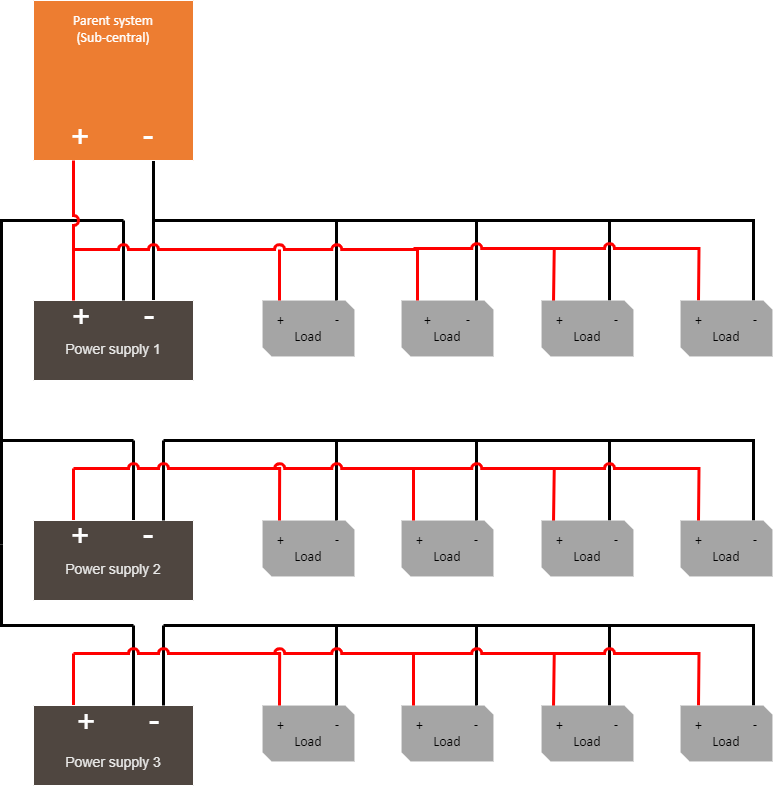

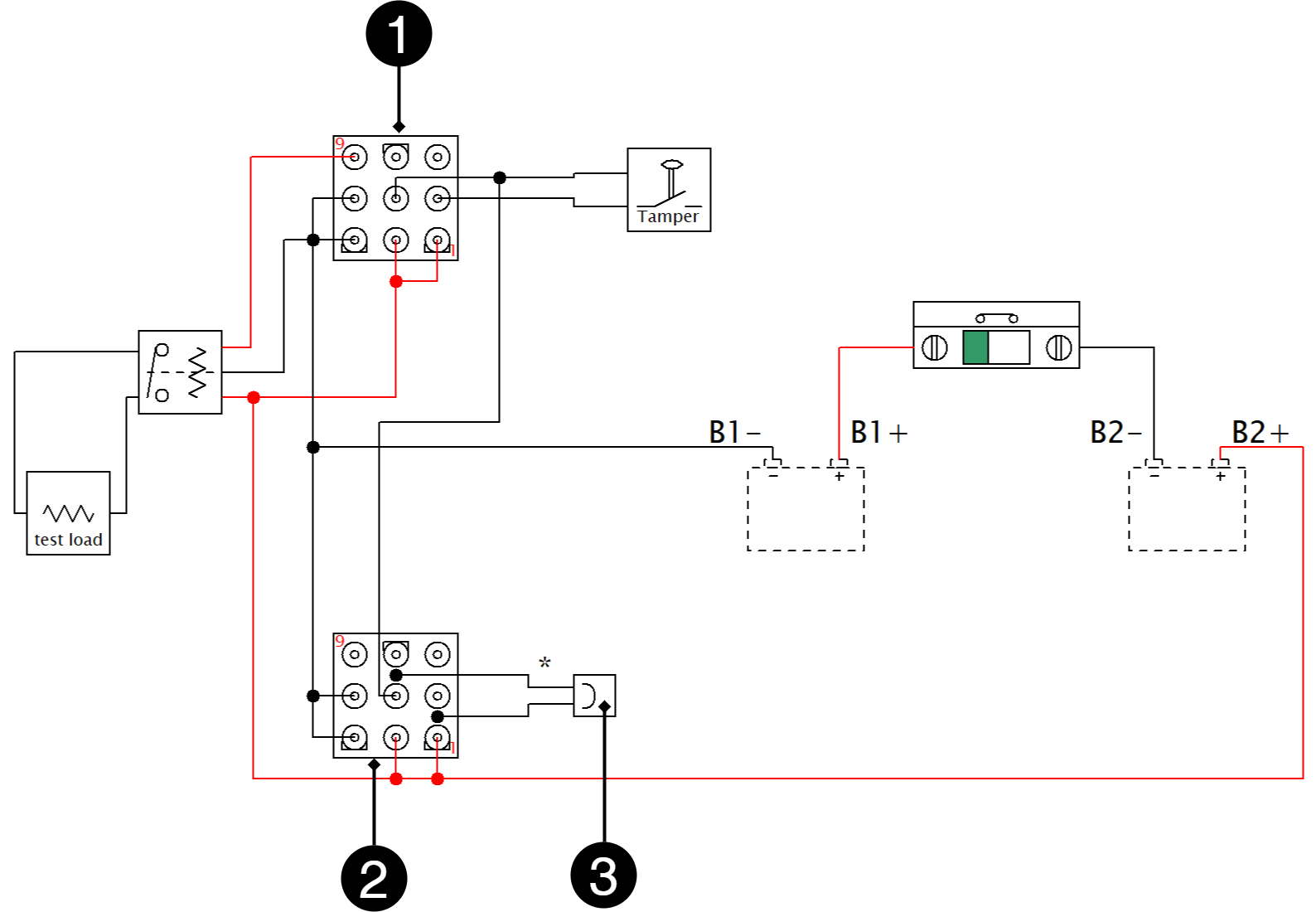

Multiple units into one parent system

To connect several units to a higher system, the load-minus between several battery backups must be connected together.

|

Commissioning - how to start the unit

connect load, alarm and possibly. other connections.

Connect batteries

Connect / switch on fuses

Screw the mains cable into the terminal block and attach the terminal block to the motherboard.

Switch on mains voltage.

Connect in this order

To minimize the risk of errors that may occur in connection with a short circuit, connections to the motherboard must be made in this order.

Nr | Explanation |

|---|---|

1 | Connect alarm. |

2 | Connect load. |

3 | Connect batteries |

4 | Connect mains. |

Important

For setting dip switches and addressing — see online manual via QR code.

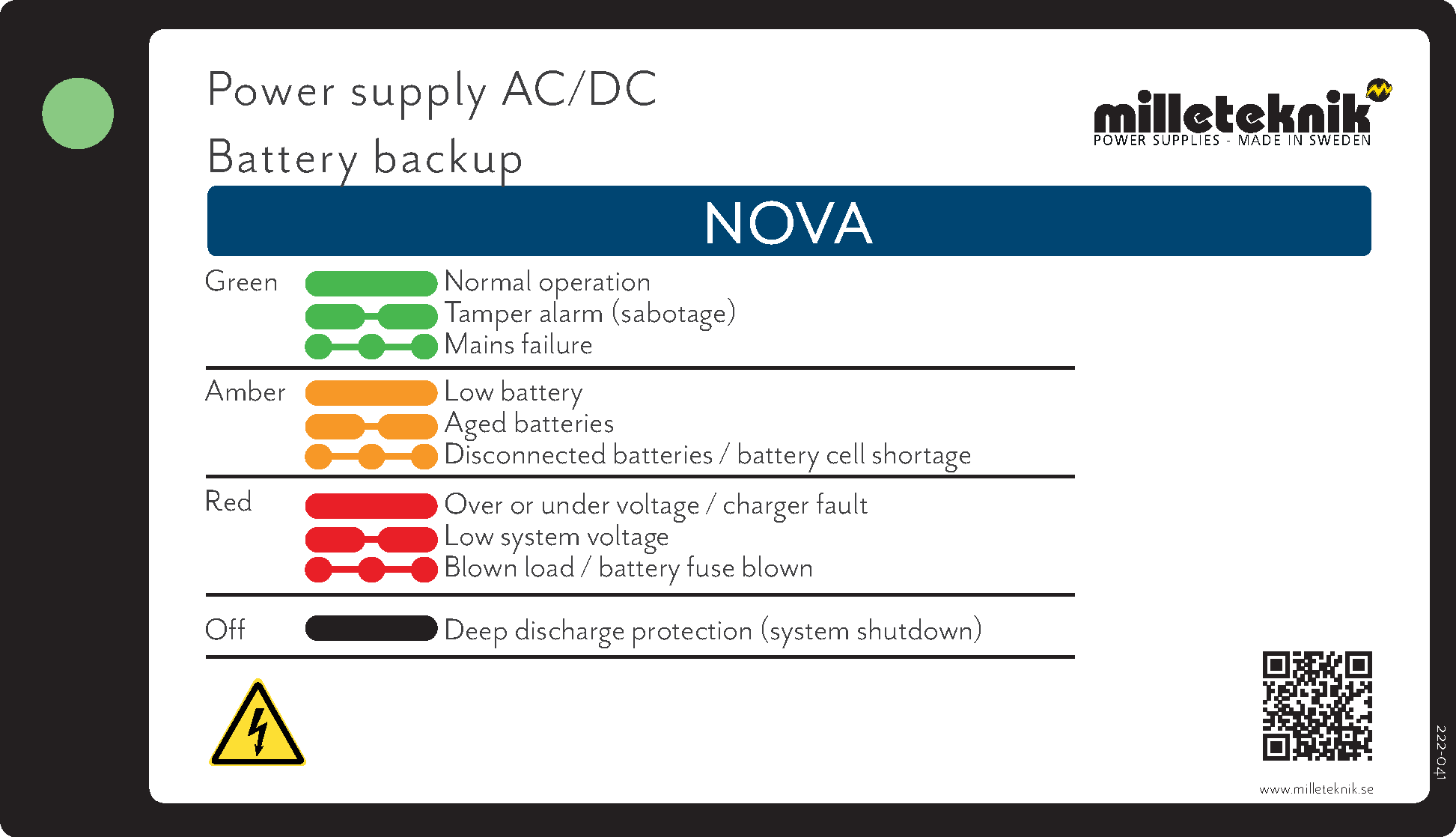

The unit works normally when the indicator LED on the outside of the cabinet door lights up with a solid green light. See front panel for other status indications.

It may take up to 72 hours before the batteries are fully charged.

System test

Test the connected device by performing a system test afterwards commissioning.

Important

Let the batteries charge for a couple of hours, use a multimeter to measure the voltage on each battery. The voltage must be at least 12.7 V per battery.

Switch on incoming mains voltage.

Indicator LED on the outside of the cabinet door lights up with a solid green light. Disconnect the mains voltage to check that the unit is operating in battery mode and alarms.

LED on the cabinet door indicates, see panel for alarm type.

Switch on incoming mains voltage. Indicator LED, on the outside of the cabinet door, lights up with a solid green light. Normal operation.

Recovery

Reset the unit by completely de-energizing the unit.

Disconnect battery wiring and mains voltage and reconnect after 5 seconds.

Alarm displayed on cabinet door

In normal mode, the indicator LED shows a solid green light.

|

The indicator diode (LED) shows | Explanation |

|---|---|

Solid green light | Normal operation. |

Slow green flashes | Sabotage alarm. |

Fast green flashes | Mains failure. |

Solid yellow light | Low battery voltage. |

Slow yellow flashes | Aged batteries. |

Rapid yellow flashes | Disconnected batteries or battery cell shortage. |

Solid red light | Overvoltage or undervoltage or charger fault. |

Slow red flashes | Low system voltage. |

Rapid red flashes | Blown load or battery fuse has blown. |

No light / off | Deep discharge protection is activated. (System shutdown). |

When operating system: If the indicator LED is off, deep discharge protection has come into force.

Notice

If the indicator light flashes every 15 seconds, the battery is fully charged and the charge is in rest phase to extend battery life. In the event of a power failure during the rest phase, the battery backup switches to battery operation as usual

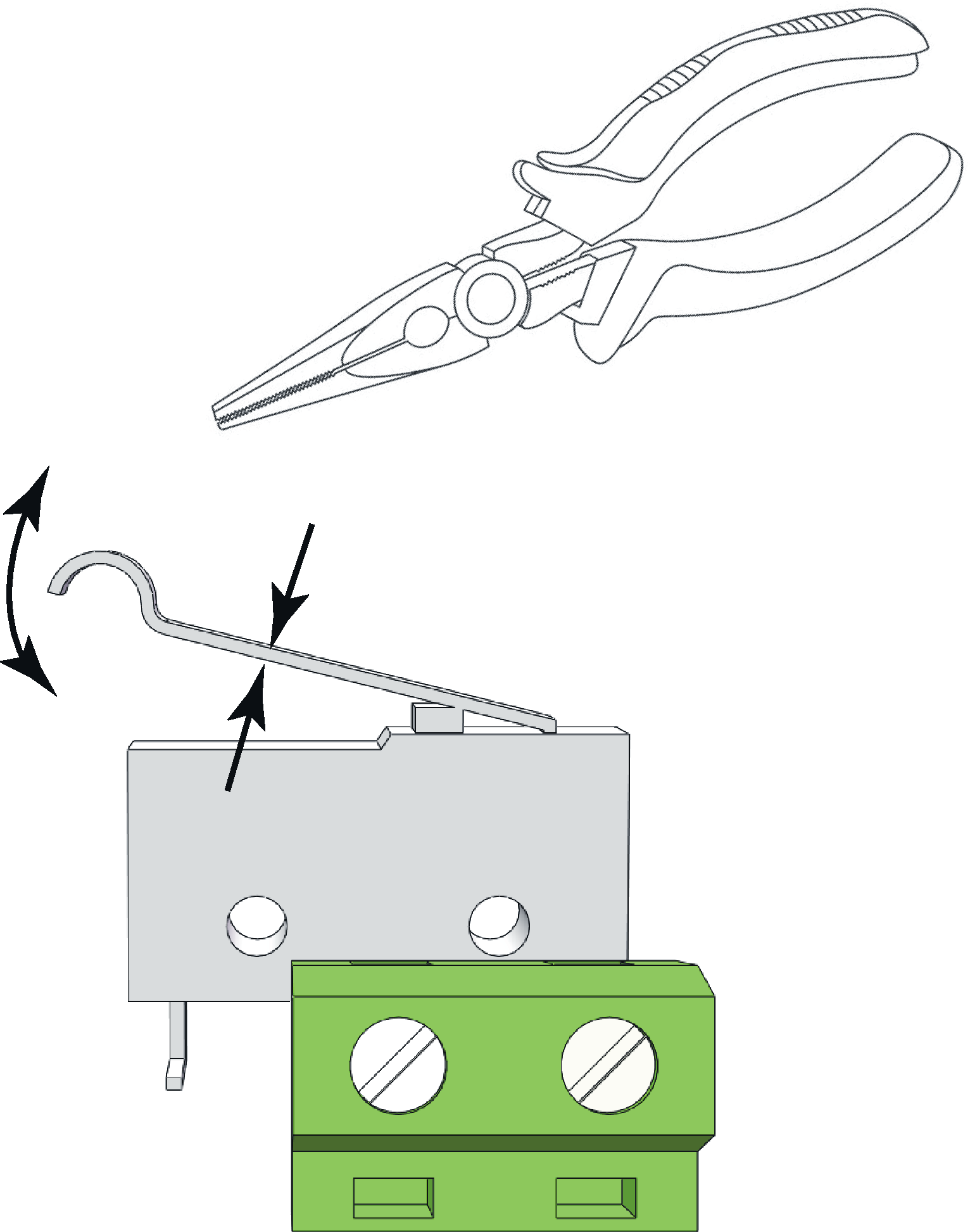

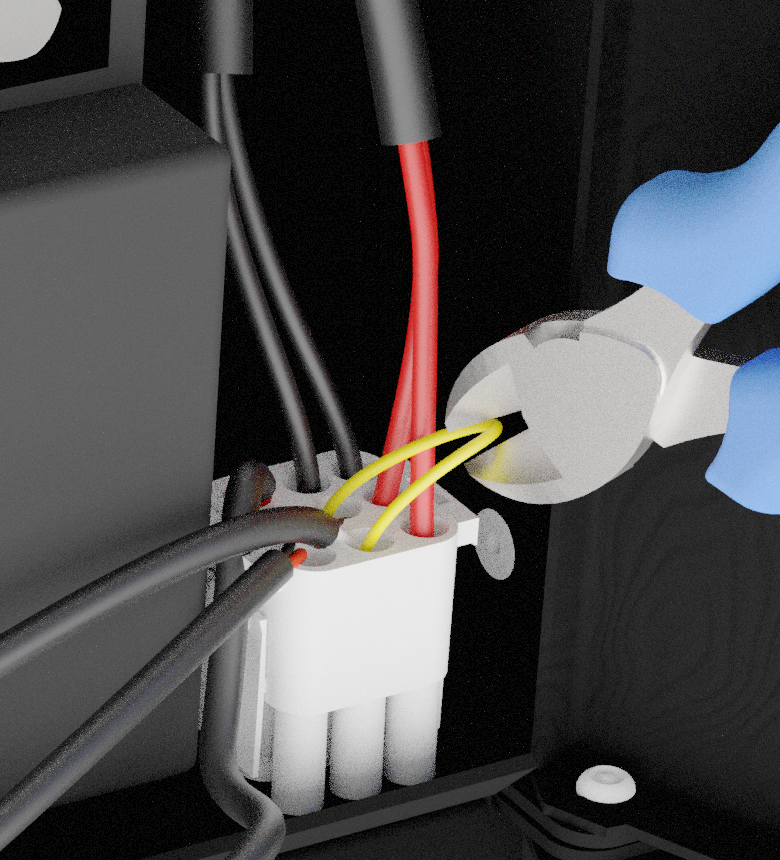

Adjustment of tamper switch

|

The tamper switch lever must be in the closed position when the cabinet door is closed. If the alarm goes off ("tamper alarm"), the lever may needs to be adjusted.

The lever is adjusted by the following steps:

Pinch with pliers in the middle of the lever.

Carefully adjust the lever in the desired direction (up / down).

Check by closing the door. A click is heard when the contact is closed.

Notice

Tamper switch will not give an alarm when closed and locked the door.

Maintenance

The system with the exception of batteries is maintenance-free when installed in an indoor environment.

Check the fan annually. The fan should rotate smoothly without any noise. Clean the fan from dust and dirt. The fan must be replaced if it does not rotate smoothly or is so dirty that it cannot be completely cleaned. If the fan does not work well, the air flow in the unit will be obstructed, which leads to an increase in heat in the enclosure, which can lead to a deterioration of the battery capacity and to a significantly shorter battery replacement interval.

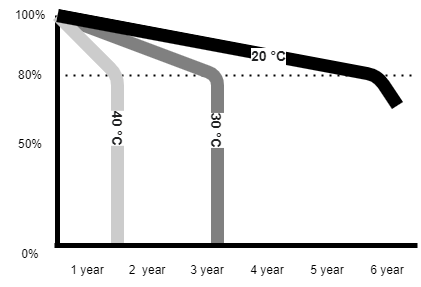

About batteries

Batteries generate electricity through a chemical process and there is thus a natural degradation of capacity. The biggest factor in battery life is temperature. The higher the temperature, the shorter the battery life. The date of manufacture stamped on the battery and the service life (as stated by the battery manufacturer). An ideal temperature is 20 °C both in operation and in storage. Higher ambient temperature greatly reduces the service life. Thus, actual lifespan varies when used. Batteries should be replaced after half specified (from the battery manufacturer) lifetime for safe operation. Batteries purchased through the manufacturer of the battery backup have a lifespan (from the battery manufacturer) of between 10-12 years with recommended replacement after 5-6 years.

[sv] Tillverkarens angivna livslängd[a] | [sv] Batteri i drift bör bytas efter[b]. | ||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

[sv] 3-5 år | [sv] 2-3 år | ||||||||||||||||||||||||||||||||||||||||||||||||

[sv] 6-9 år | [sv] 3-5 år | ||||||||||||||||||||||||||||||||||||||||||||||||

[sv] 10-12 år | [sv] 5-7 år | ||||||||||||||||||||||||||||||||||||||||||||||||

[sv] 15+ år | [sv] 8-10 år | ||||||||||||||||||||||||||||||||||||||||||||||||

[a] Gäller vid helt outnyttjat batteri som är lagrat under optimala förhållanden. [b] Vid drift i idela omgivningstemperatur, 20 °C. | |||||||||||||||||||||||||||||||||||||||||||||||||

battery change

If possible, disconnect mains (voltage) when replacing the battery.

Disconnect battery cables. Note how battery cables are mounted before removing them.

Remove battery fuse between batteries.

Insert and fasten the new batteries.

Connect the battery cables in the same way as before.

Connect battery fuse between batteries.

Switch on mains voltage. The indicator LED may not be green (up to 72 hours), until the batteries are charged.

Test the system by briefly disconnecting the mains voltage, (= the load is driven by the batteries), and then switch on the mains voltage again.

Battery recycling

All batteries must be recycled. Return to manufacturer or return to recycling station.

Safety Information - Service and Troubleshooting

If possible, disconnect the mains supply before starting any work, such as servicing, battery replacement, metering or troubleshooting.

Remove the battery fuse/plug before working on the DC side.

Check that all cables are properly connected and grounded before re-energizing the unit.

The product may contain components that become hot during operation. Avoid touching internal parts immediately after the power has been switched off.

If fuses disengage repeatedly see Troubleshooting or disconnect the device and contact Milleteknik technical support.

In case of suspicion of damage, liquid ingress or burnt odour, the product must not be used until it has been checked by competent personnel.

During operation, the housing should be closed and locked (if the device has a lock).

Only authorized service personnel may perform repairs on the device.

Use only original fuses and batteries of the same type and value as specified in the manual/product sheet.

Milleteknik is not responsible for damage caused by improper handling, modification or unapproved components.

Troubleshooting

If the device does not work as expected, go through the following checks:

Problem | Possible cause | Action |

|---|---|---|

No output voltage. | No mains voltage, fuse triggered or battery failure. | Check the supply, fuses and battery connections. |

Battery does not charge. | Faulty battery connection or battery fuse has blown. | Check battery cables and replace battery fuse if necessary. |

The device starts but alarms. | Batteries not sufficiently charged or faulty load or battery. | Wait 72 hours until the batteries are fully charged. Ensure that the connected load does not exceed the rated current. |

LED flashes. | Information, warning or error. | See panel or manual for explanation. |

Fuses blow frequently. | Short circuit or overload. | Check connected devices, change the fuse only after the cause is fixed. |

The device gets hot | High load or insufficient ventilation | Check that the rated current is not exceeded and that air flow is present around the housing. |

If the problem persists after these checks, contact Milleteknik support and provide the product name, serial number and a brief error description.

NOVA product sheet

SSF1014 certified battery backup with communication

|

NOVA FLX L can be mounted on a wall or in a 19" rack.

Technical specifications

These technical specifications are subject to change without notice.

Name, article number and e-number

Name | Article number | E-number |

|---|---|---|

NOVA 24V 10A FLX L | FL01P30024P100-SSF | 52 135 70 |

NOVA 24V 5A FLX L | FL01P30024P050-SSF | 52 135 69 |

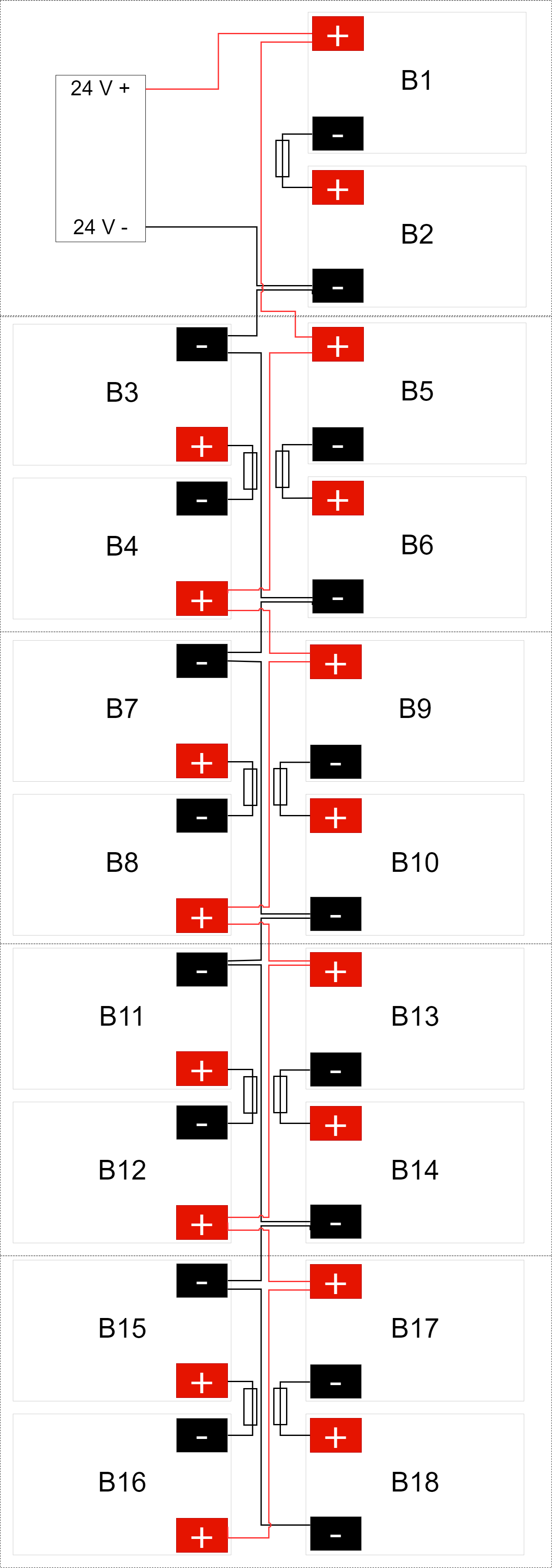

About NOVA FLX

NOVA FLX is mainly used in safety systems where SSF 1014 approved battery backup is required or where the requirements are higher. Requirements such as better flexibility, more alarm functions, longer backup operating times or where the battery backup needs to handle higher loads.

The NOVA series is system certified according to SSF1014 together with most systems on the Swedish market. Milleteknik has the right to sell two different systems on the Swedish market; Sentrion NOVA The series has communication via RS485 to Sentrion S4, S4 DUO and CISS. Integra. Together with MOVEO kit (optional) there is RS232 communication with Integra MOVEO and MOVEO XL.

Flexibility

NOVA FLX S can have an extra battery box. NOVA FLX M and NOVA FLX L with 1-4 extra battery boxes *. NOVA FLX M and NOVA FLX L with battery shelves in 19 ”rack *. * The battery boxes and shelves are connected via a 9-pin connector. The battery box has room for up to 2 pcs. 45 Ah batteries per battery box. Battery shelves have room for 2 pcs. 45 Ah batteries (Medium) and up to 2 pcs. 150 Ah batteries (Large) per each battery shelf.

Fixed installation

The product is intended for fixed installation. The battery backup must be installed by a qualified installer.

Area of use

NOVA FLX mostly used for: Access control system, burglar alarms, (integrated security systems), in public environments such as schools, offices and commercial properties.

Installation video

Regulations and certifications

Standards that product (s) meet and are approved for

SBF 110:8 |

SSF1014 Alarm class 1-4 (burglar alarm). |

SSF1014, Issue 5. |

Certificate number, SBSC | Designation SBSC |

|---|---|

No. 18-246 | NOVA 27 250-FLX, NOVA 27 150-FLX, NOVA 27 100-FLX, NOVA 27 50-FLX, NOVA 13 100-FLX, NOVA 27 100-XS2, NOVA 27 50-XS2, NOVA 27 30-XS2, NOVA 13 100-XS2, NOVA 13 50-XS2 |

No. 20-117 | NOVA 27 50-FLX S • NOVA 27 100-FLX S • NOVA 27 50-FLX M • NOVA 27 100-FLX M • NOVA 27 150-FLX M • NOVA 27 250-FLX M • NOVA 27 50-FLX L • NOVA 27 100-FLX L • NOVA 27 150-FLX L • NOVA 27 250-FLX L Unison Facility Cabinet |

Certificate number, RiSE |

|---|

SC0204-19 |

Requirements that the product meets

EMC: | EMC Directive 2014 / 30EU |

CE: | EC Directive in force: 765/2008 |

Emissions: | EN61000-6-:2001 EN 55022:1998: -A 1:2000, A 2:2003 Class B, EN61000-3-2:2001, EN 55032 (replaces EN 55022) |

Machinery Directive | The product is part of electrical systems, is subject to the relevant electrical and safety directives and is not a machine according to the Machinery Directive (2006/42/EC). |

Ecodesign | Milleteknik's products are intended for professional use and are therefore not directly covered by the Ecodesign Regulation (EU 2019/1782). As some components may be covered, we nevertheless disclose relevant information to give our customers confidence in their choice |

Reserve operating times, power outlet and load output current

Charging current for batteries and battery capacity

The unit reads the connected system load and charges the batteries with available residual current from the power supply. The device performs qualified* battery tests and notifies when batteries need to be replaced. The batteries are charged gently to extend their life and protection is available against overcharging.

12 V / 24 V | Maximum charging current for batteries |

|---|---|

NOVA FLX L | 6 A |

The battery backup has controlled charging ** (controlled charging) which prevents batteries from being overcharged and extends their service life significantly. The NOVA series must be used with AGM batteries.

24 V | Battery capacity | Maximum battery capacity with 1 battery box | Maximum battery capacity with 2 battery boxes | Maximum battery capacity with 3 battery boxes | Maximum battery capacity with 4 battery boxes |

|---|---|---|---|---|---|

NOVA FLX L, 24 V | 45 Ah (2 pcs 45 Ah) | 90 Ah (4 x 45 Ah) | 135 Ah (6 x 45 Ah) | 180 Ah (8 x 45 Ah) | 225 Ah (10 x 45 Ah) |

Power outlet NOVA FLX

NOVA 24V 5A FLX L | Unit without battery box | Unit with 1 battery box | Unit with 2 battery boxes | Unit with 3 battery boxes | Unit with 4 battery boxes |

|---|---|---|---|---|---|

Battery | 2 pcs. 45 Ah | 4 st 45 Ah | 6 st 45 Ah | 8 st 45 Ah | 10 st 45 Ah |

Max battery capacity | 45 Ah | 90 Ah | 135 Ah | 180 Ah | 225 Ah |

According to. SSF1014, Alarm Class 1-2 | 3.7 A | 7.4 A | 11.2 A | 14.9 A | 18.7 A |

According to. SSF1014, Alarm Class 3-4 | 1.5 A | 3.0 A | 4.5 A | 6.0 A | 7.5 A |

Imax A (max discharge current) | 5 A | 5 A | 5 A | 5 A | 5 A |

Imax b (max charging current) | 5 A | 5 A | 5 A | 5 A | 5 A |

Imin is always 0 A. | |||||

NOVA 24V 10A FLX L | Unit without battery box | Unit with 1 battery box | Unit with 2 battery boxes | Unit with 3 battery boxes | Unit with 4 battery boxes |

|---|---|---|---|---|---|

Battery | 2 pcs. 45 Ah | 4 st 45 Ah | 6 st 45 Ah | 8 st 45 Ah | 10 st 45 Ah |

Max battery capacity | 45 Ah | 90 Ah | 135 Ah | 180 Ah | 225 Ah |

According to. SSF1014, Alarm Class 1-2 | 3.7 A | 7.4 A | 11.2 A | 14.9 A | 18.7 A |

According to. SSF1014, Alarm Class 3-4 | 1.5 A | 3.0 A | 4.5 A | 6.0 A | 7.5 A |

Imax A (max discharge current) | 10 A | 10 A | 10 A | 10 A | 10 A |

Imax b (max charging current) | 10 A | 10 A | 10 A | 10 A | 10 A |

Imin is always 0 A. | |||||

Permitted average load according to SSF1014 Alarm class 1-4:

Permitted average load according to SSF1014 Alarm class 1-4: | NOVA 24V 5A FLX L | NOVA 24V 10A FLX L | NOVA 24V 25A FLX L | MOVA 24V 25A FLX L |

|---|---|---|---|---|

FLX M without battery box according to Alarm class 1-2 / 3-4 | 3.7 A / 1.5 A | 3.7 A / 1.5 A | 3.6 A / 1.4 A | 3.6 A / 1.4 A |

Including 1 pc. Battery box FLX M, according to Alarm class 1-2 / 3-4: | - | 7.4 A / 3 A | 7.3 A / 2.9 A | 7.3A / 2.9A |

Including 2 pcs. Battery box FLX M, according to Alarm class 1-2 / 3-4: | - | - | 11.1 A / 4.4 A | 11.1 A / 4.4 A |

Including 3 pcs. Battery box FLX M, according to Alarm class 1-2 / 3-4: | - | - | - | 14.8A / 5.9A |

Including 4 pcs. Battery box FLX M, according to Alarm class 1-2 / 3-4: | - | - | - | 18.7A / 7.5A |

Reserve operating times for different alarm classes - overview

Alarm class | Spare operating time in the event of a power failure | Maximum number of hours of battery recharging (80%) |

|---|---|---|

EN54-4 | - | 24 h |

SBF110: 8 | 30 h + 10 min | 24 h |

EN50131-6 grades 1-2 | 12 h | 72 h |

EN50131-6 grade 3 | 24 h | 24 h |

SSF1014 Alarm class 1/2 | 12 h | 72 h |

SSF1014 Alarm class 3/4 | 30 h | 24 h |

The table shows the requirements for backup operating time and recharging of batteries for different alarm classes.

Circuit boards - Technical data

Technical data, motherboard: PRO 3

Info | Explanation |

|---|---|

Short name: | PRO 3 |

Product description | Motherboard in battery backup with advanced functions and communication to parent system. |

Own consumption, with relay card | Less than 100 mA. All relays retracted on external alarm card in normal mode. |

Switching time from mains voltage to battery operation | When batteries are idle: <5 microseconds. When batteries are in charge cycle: 0 (none). Batteries rest for 20-day cycles, after which a charging cycle picks up and charges the batteries for 72 hours. If there is a power failure when batteries are in the charge cycle, there is no switching time. |

Incoming electricity network | 230 V AC -240 V AC, 47-63 Hz. |

Fuse on mains | See table: Fuses. |

Indication | Indicator diode on circuit board / cabinet door |

Alarm

Alarm displayed on indicator LED on the front of the cabinet.

Cell fault in battery or unconnected battery.

Charger fault, undervoltage.

Charger fault, overvoltage.

Low system voltage, system voltage below 24.0 V in mains operation.

Low battery voltage, below 24.0 V DC in case of mains failure.

Power failure alarm.

Sabotage switch.

Fuse fault.

Aged battery

Expanding alarm functions are available via communication or with alarm cards.

Fuses | Type |

|---|---|

5 A | T5A |

10 A | T10A |

Mains fuse for 24 V units up to 15 A | T2.5AH250V. Ceramic. |

Info | Explanation |

|---|---|

Deep discharge protection (Yes / No) | Yes. 12 V units protection at 10V, +/- 0.5 V. 24 V units protection at 20, +/- 0.5 V. |

Surge protection (Yes / No) | Yes |

Overtemperature protection (Yes / No) | Yes |

Short circuit protected = (Yes / No) | Yes |

Technical data, alarm card for PRO 3 / NEO3

Info | Explanation |

|---|---|

Card name: | PRO 3 |

Version: | 1.2 |

Product description | Motherboard in battery backup with advanced functions and communication to superior systems. |

Recommended environment | Indoors, class 1. Ambient temperature: + 5 ° C - 40 ° C. |

Protection class | IPX0 |

Recommended installation | NOVA Series (only 5 A and 10 A) |

Input voltage | 13.6 VDC, 27.3 VDC |

Self-consumption | 40 mA |

Alarm via | Alternating relay |

Number of alarm outputs | 4 pcs |

Certified according to | EN 50131-6, SBF 110: 8, SSF1014, Meets alarm class 4, SSF 1014, edition 5 |

Certificate number (SBSC) | 20-117 |

The product meets the requirements according to | CE directive according to: 765/2008, EMC Directive 2014 / 30EU, Emission: EN61000-6-: 2001, EN55022: 1998: -A1: 2000, A2: 2003 Class B, EN61000-3-2: 2001, Immunity: EN61000- 6-2: 2005, EN61000-4-2, -3, 4, -5, -6, -11. SS-EN 50 130-4: 2011 Edition 2 & SSF1014 Alarm class 1-4 (Burglar alarm). |

Producer | Milleteknik AB |

Country of origin | Sweden |

Alarm overview in alphabetical order | Relay 1 * / Alarm output 1 | Relay 2 * / Alarm output 2 | Relay 3 * / Alarm output 3 | Relay 4 * / Alarm output 4 | Communication (P5: 1-9) | Indicator LED on main card and LED on door. |

|---|---|---|---|---|---|---|

Network outages | X | - | - | - | X | X |

Fuse fault | - | X | - | - | X | X |

Sabotage switch | - | - | - | X | X | X |

Fan fault | - | - | - | - | X | - |

Charger fault, overvoltage | - | X | - | - | X | X |

Charger fault, undervoltage | - | X | - | - | X | X |

Cell fault or unconnected battery | - | X | - | - | X | X |

Low system voltage. ** | - | - | X | - | X | X |

Low battery voltage (<24.0 V DC) or power failure | - | X | - | - | X | X |

Overtemperature | - | - | - | - | X | - |

Undertemperature | - | - | - | - | X | - |

Undertemperature | - | - | - | - | X | - |

Short battery life left | - | - | - | - | X | - |

Aged battery | - | X ** | - | - | X ** | X ** |

Overcurrent 100%, minute average | - | - | - | - | X | - |

Overcurrent 80%, daily average | - | - | - | - | X | - |

Overcurrent 175%, second average | - | - | - | - | X | - |

* Alarm on potential-free relay contact. *** Not on NEO battery backups. | ||||||

RS-485 on P4: 1-4 | Explanation |

|---|---|

P4:1 | GND |

P4:2 | RX |

P4:3 | TX |

P4:4 | +5V |

Power supply

Power supply - Technical Data LRS-150-24

In: |

|---|

NOVA 24V 5A FLX L |

Info | Explanation |

|---|---|

Output voltage | 27.3 V |

Output current: | 0 A - 6.5 A |

Output voltage, ripple | 200 mVp-p |

Overvoltage | 28.8 V - 33.6 V |

Voltage recharge, ripple / current limitation | Less than 0.6 Vp-p |

Efficiency | 89% |

Current limitation | 110% - 140% |

Constant voltage | +/- 0.5% |

Regulatory accuracy | + / - 1.0% |

Input current (230 V) | 1,7 A |

Mains voltage frequency | 47 Hz- 63 Hz |

Mains voltage | 230 V AC - 240 V AC |

Brand effect | 156 W |

Temperature range | -30°C - +70°C |

Humidity range | 20% - 90% RH non-condensed |

Power supply - Technical Data RSP-320-24

In: |

|---|

NOVA 24V 10A FLX L |

Info | Explanation |

|---|---|

Output voltage | 27.3 V |

Output current | 0 A - 13.4 A |

Output voltage, ripple | 150 mVp-p |

Overvoltage | 27.6 V - 32.4 V |

Voltage recharge, ripple / current limitation | Less than 1.2 Vp-p |

Efficiency | 89% |

Current limitation | 105% - 135% |

Constant voltage | +/- 0.5% |

Regulatory accuracy | +/- 1.0% |

Input current (230 V) | 2 A |

Mains voltage frequency | 47 Hz- 63 Hz |

Mains voltage | 230 V AC - 240 V AC |

Brand effect | 321.6 W |

Temperature range | -30°C - +70°C |

Humidity range | 20% - 90% RH non-condensed |

Technical data enclosures

Enclosures - Technical Data FLX L

Info | Explanation |

|---|---|

Name | FLX L |

Enclosure class | IP 32 |

Measure | Height: 444 mm, width 438 mm, depth 212 mm |

Height units | 10 HE |

Mounting | Wall or 19 "rack |

Ambient temperature | + 5 ° C - + 40 ° C. For best battery life: + 15 ° C to + 25 ° C. |

Environment | Environmental class 1, indoors. 20% ~ 90% relative humidity |

Material | Powder coated sheet |

Color | Black |

Cable entries, number | 4 |

Batteries that fit | 2 st 12 V 45 Ah |

Place for fan | Yes |

Link to the latest information

Products and software are subject to updates, you will always find the latest information on our website.

Warranty, support, country of manufacture and country of origin

Warranty 5 years

The product has a five-year warranty, from the date of purchase (unless otherwise agreed). Free support during the warranty period is reached at support@milleteknik.se or telephone, +46 31-34 00 230. Compensation for travel and or working hours in connection with the location of faults, installation of repaired or replaced goods is not included in the warranty. Contact Milleteknik for more information. Milleteknik provides support during the product's lifetime, however, no later than 10 years after the date of purchase. Switching to an equivalent product may occur if Milleteknik deems that repair is not possible. Support may be added (at Millteknik's desrection) after the warranty period has expired.

Manufacturer support

Manufacturers provide support for the life of the product, however, for a maximum of 10 years after the date of purchase. Switching to an equivalent product may occur if the manufacturer deems that repair is not possible. Support costs will be added after the warranty period has expired.

Support

Do you need help with installation or connection?

You will find answers to many questions at: www.milleteknik.se/support

Phone: +46 31-340 02 30

Support is open: Monday-Thursday 08:00-16:00, Fridays 08:00-15:00. Closed 11:30-13:15.

Spare parts

Contacted support for questions about spare parts.

Support after the warranty period

Milleteknik provides support during the life of the product, but no longer than 10 years after the date of purchase. Replacement for an equivalent product may occur if the manufacturer deems that repair is not possible. Costs for support and replacement are added after the warranty period has expired.

Questions about product performance?

Contact sales: 46 31-340 02 30, e-mail: sales@milleteknik.se

Contact us

Milleteknik AB

Ögärdesvägen 8 B

S-433 30 Partille

Sweden

+46 31-34 00 230

www.milleteknik.se

Country of manufacture

Country of manufacture / country of origin is Sweden. For more information, contact your seller.

Designed and produced by: Milleteknik AB

Designed and produced by Milleteknik AB

Product life cycle, environmental impact and recycling

The product is designed and constructed for a long service life, which reduces the environmental impact. The product's service life depends on, among other things, environmental factors, mainly ambient temperature, unforeseen load on components such as lightning strikes, external damage, handling errors, and more. Products are recycled by being handed over to the nearest recycling station or sent back to the manufacturer. Contact your distributor for more information. Costs that arise in connection with recycling are not reimbursed.

Batteries - recommended, not included

Batteries are not included they are sold separately

Batteries are sold separately.

Battery combinations NOVA FLX L

Battery capacity (Ah) | Battery type | Number of batteries | Batteries in unit |

|---|---|---|---|

45 Ah | 45 Ah | 2 pcs. | 2 in Battery Backup |

90 Ah | 45 Ah | 4 pcs | 2 in Battery Backup 2 in Battery Box 1 |

155 Ah | 45 Ah | 6 pcs | 2 in Battery Backup 2 in Battery Box 1 2 and Batteribox 2 |

180 Ah | 45 Ah | 8 pcs | 0 in Battery Backup 2 in Battery Box 1 2 and Batteribox 2 2 and Batteribox 3 |

225 Ah | 45 Ah | 10 pieces. | 2 in Battery Backup 2 in Battery Box 1 2 and Batteribox 2 2 and Batteribox 3 2 and Batteribox 4 |

Certified with battery type

The device is certified with a UPLUS battery that must be used to maintain the certificate.

45 Ah, 12 V AGM battery

Fits in | Number of batteries |

|---|---|

NOVA 24V 5A FLX L | 2 |

NOVA 24V 10A FLX L | 2 |

Battery type | V | Ah |

|---|---|---|

Maintenance-free AGM, lead-acid battery. | 12 V | 45 Ah |

Article number | E-number | Article name | Terminal | Measure. Height width depth | Weight per piece | Make |

|---|---|---|---|---|---|---|

MT113-12V45-01 | 5230546 | UPLUS 12V 45Ah 10+ Design Life battery | M5 Bult | 197x165x170 mm | 14.5 kg | UPLUS |

Reserve operating times for different alarm classes - overview

The table shows the requirements for backup operating time and recharging of batteries for different alarm classes.

Important

This is a guide and all times are approximate and may differ from actual times. Load, temperature and other factors come into play, which is why exact time can not be provided.

Applies to new batteries.

Amperage and batteries vary with configuration, check if the configuration can handle batteries and amperage.

Medium current | 7.2 Ah | 14 Ah | 28 Ah | 45 Ah |

|---|---|---|---|---|

Loading | Backup operating time (approx.), Minutes | |||

0.5 A | 450 | 820 | 1650 | 2350 |

1 A | 260 | 485 | 970 | 1460 |

2 A | 150 | 280 | 560 | 920 |

4 A | 90 | 165 | 335 | 550 |

6 A | 67 | 125 | 245 | 405 |

8 A | 57 | 105 | 210 | 350 |

10 A | 44 | 80 | 160 | 270 |

12 A | 38 | 70 | 140 | 235 |

14 A | 33 | 60 | 120 | 200 |

16 A | 28 | 50 | 100 | 170 |

18 A | 25 | 45 | 89 | 150 |

20 A | 23 | 42 | 84 | 142 |

Medium current | 28 Ah | 42 Ah | 65 Ah | 70 Ah |

|---|---|---|---|---|

- | 4 batteries (14 Ah) | 6 batteries (14 Ah) | 4 batteries (20Ah + 45 Ah) | 10 batteries (7 Ah) |

Loading | Backup operating time (approx.), Minutes | |||

0.5 A | 1650 | 2090 | 5574 | 3440 |

1 A | 970 | 865 | 3252 | 2118 |

2 A | 560 | 815 | 1770 | 1329 |

4 A | 335 | 490 | 930 | 864 |

6 A | 245 | 360 | 600 | 605 |

8 A | 210 | 310 | 426 | 544 |

10 A | 160 | 240 | 342 | 414 |

12 A | 140 | 210 | 270 | 363 |

14 A | 120 | 180 | 234 | 311 |

16 A | 100 | 150 | 204 | 286 |

18 A | 90 | 130 | 150 | 254 |

20 A | 84 | 126 | 138 | 241 |

Medium current | 90 Ah | 110 Ah | 135 Ah | 155 Ah |

|---|---|---|---|---|

- | 4 batteries (45 Ah) | 6 batteries (20 Ah + 45 Ah) | 6 batteries (45 Ah) | 8 batteries (20 Ah + 45 Ah) |

Loading | Backup operating time (approx.), Minutes | |||

0.5 A | 4705 | 5796 | 7056 | 8215 |

1 A | 2928 | 3582 | 4392 | 5070 |

2 A | 1836 | 2247 | 2754 | 3230 |

4 A | 1183 | 1438 | 1762 | 2018 |

6 A | 788 | 959 | 1175 | 1345 |

8 A | 748 | 861 | 1048 | 1150 |

10 A | 570 | 689 | 839 | 920 |

12 A | 499 | 603 | 699 | 765 |

14 A | 427 | 516 | 629 | 655 |

16 A | 404 | 499 | 592 | 590 |

18 A | 359 | 444 | 526 | 520 |

20 A | 340 | 420 | 498 | 495 |

Medium current | 180 Ah | 200 Ah | 225 Ah |

|---|---|---|---|

- | 8 batteries (45 Ah) | 10 batteries (20 Ah + 45 Ah) | 10 batteries (45 Ah) |

Loading | Backup operating time (approx.), Minutes | ||

0.5 A | 9408 | 12972 | 11760 |

1 A | 5856 | 7872 | 7320 |

2 A | 3672 | 4548 | 4590 |

4 A | 2365 | 2670 | 2945 |

6 A | 1577 | 1780 | 1960 |

8 A | 1500 | 1558 | 1800 |

10 A | 1140 | 1246 | 1410 |

12 A | 950 | 1038 | 1200 |

14 A | 855 | 890 | 1055 |

16 A | 810 | 902 | 995 |

18 A | 715 | 802 | 885 |

20 A | 680 | 722 | 840 |

Subject to typos.

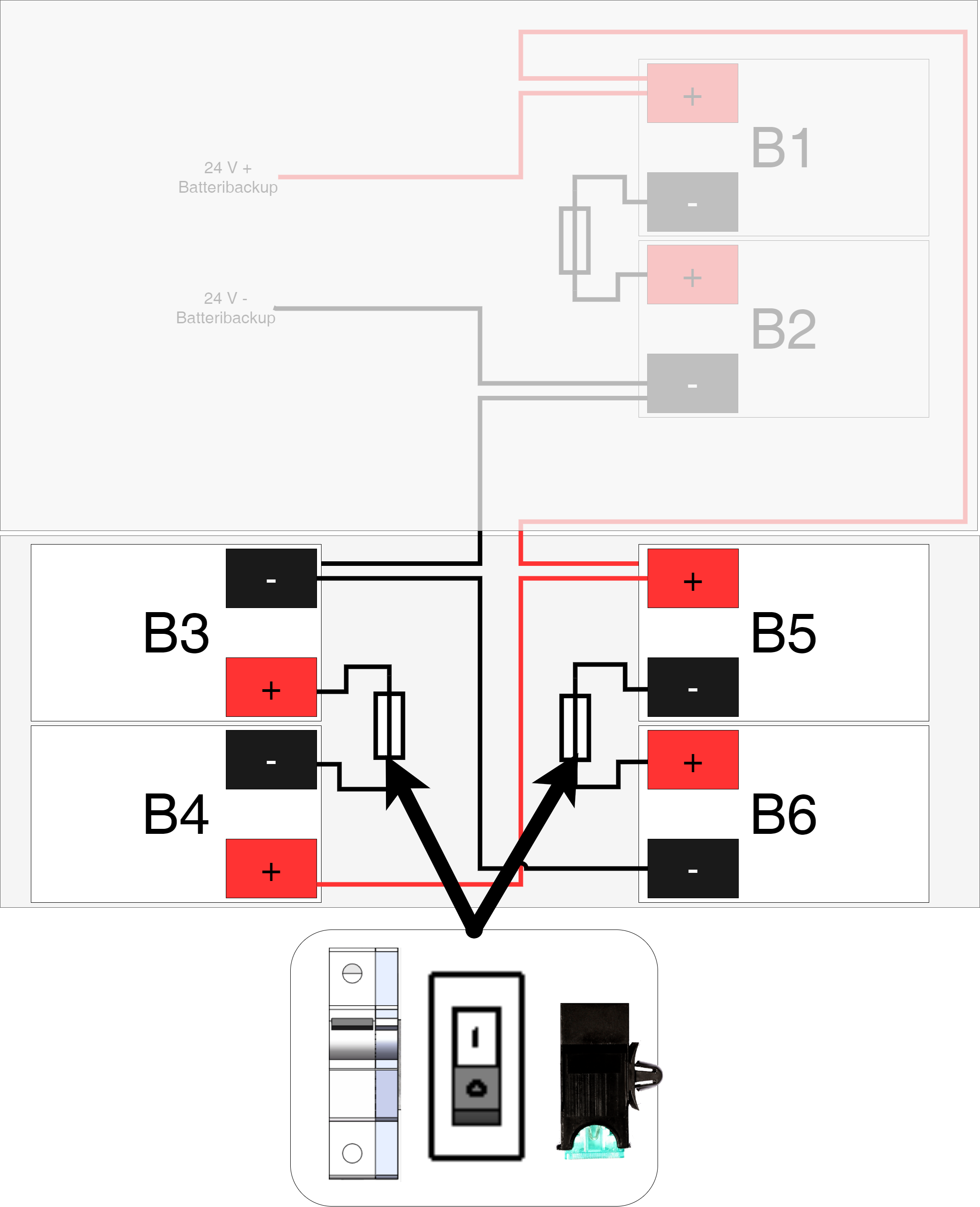

Connection of battery box

Connecting batteries in FLX M

Note that cards (4) differ from different configurations.

Nr | Explanation |

|---|---|

1 | + and - battery cable from battery fuse. |

2 | Battery fuse. |

3 | + and - battery cable from motherboard. |

4 | Motherboard, varies with configuration. |

5 | Battery cables from the motherboard. |

6 | Connection for connecting the battery box. |

A | - terminal for battery cable from battery fuse. |

B | Battery fuse. |

C | - terminal for battery cable for connection to battery backup. |

D | Connection for connection to battery backup. |

Installation of battery box, what to do in battery backup

Cable gland / knock-out is located on the underside of the battery backup and must be disconnected before mounting.

The unit must be de-energized during installation and connection.

Use the wiring that comes with the battery box to meet the wiring from the battery backup. See picture.

The picture shows cable wiring from the battery backup that meets cables from the battery box

Connection of batteries battery box

Battery wiring is mounted on the circuit board upon delivery. Pictures below only show how to connect wiring.

Warning

Damage to equipment can occur due to incorrect connection.

Note

The type of fuse between batteries varies with configuration.

Connection to batterybox

The picture also gives an overview of connection points for battery cables and battery fuses.

Battery cables | Explanation |

|---|---|

B1+ | Connects to fuse . |

B1- | Cable from motherboard is connected to battery . |

B2+ | Cable from motherboard is connected to battery . |

B2- | Connects to fuse . |

B3+ | Connects to fuse . |

B3- | Connected via connector to battery in battery backup . |

B4+ | Connected via connector to battery in battery backup . |

B4- | Connects to fuse . |

Number | Explanation |

|---|---|

1 | Battery fuse. |

2 | Connect battery backup and battery box with white square connector. |

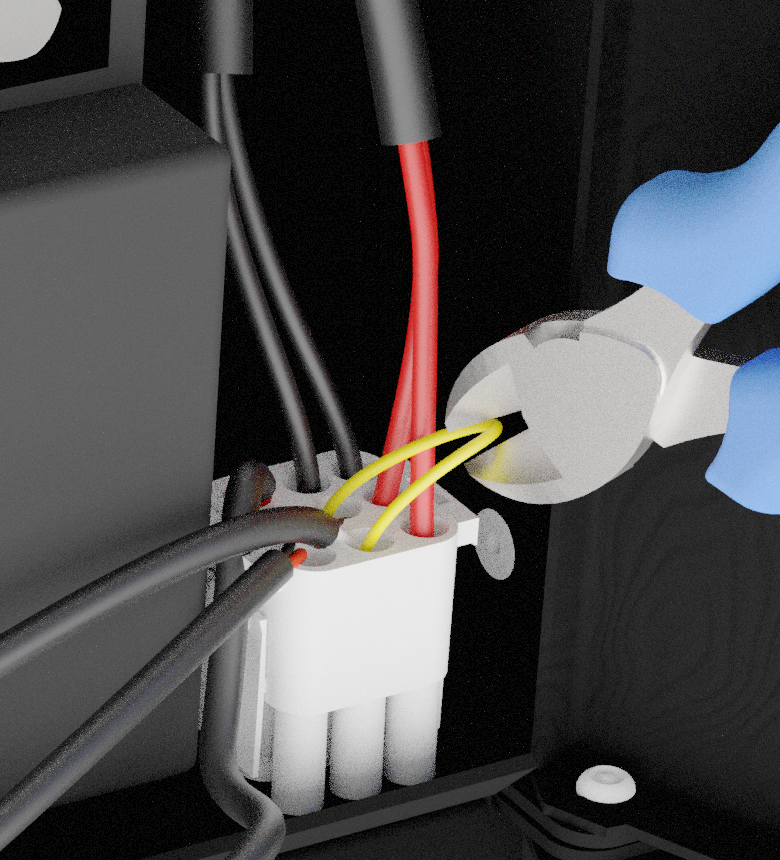

Wiring diagram and jumper

Alarms for tamper contact are connected in series and therefore the loop must be unbroken to the last battery box wiring. Jumper closes the loop on each wiring that goes from battery backup to battery box and in order for an alarm to be given on the tamper connector in the battery box, a yellow jumper on wiring must be cut. Do not cut the jumper on the last wiring in the battery box, as sabotage alarms will not be given in any connected battery backup or battery box.

Number | Explanation |

|---|---|

1 | IN - incoming connection |

2 | OUT - outgoing connection |

3 | Jumper on base on outgoing connection |

Devices | Yellow jumper - where to cut / not cut | Where the end of the loop should be |

|---|---|---|

Battery backup without battery box | Do not cut the jumper | Jumper should remain in battery backup |

Battery backup + 1 battery box | Cut jumper from battery backup | Jumper must remain in battery box 1 |

Battery backup + 2 battery boxes | Cut jumper in battery backup and from battery box 1 | Jumper must remain in battery box 2 |

Battery backup (NOVA FLX) with 4 battery boxes (NOVA FLX)

Tamper switch when using battery box(-es)

If one or more battery boxes have been connected to the unit, the tamper switch must be connected in series in order for alarms from all units to be given. It is important that the series connection ends at the last tamper contact. The series connection must start in the battery backup unit and return to the last battery box.

All tamper contacts must be in series for everyone to be part of the alarm chain. Therefore, the yellow cable that is in the jackable connector must be cut on all connecting cables, except the last on. The cable must not be cut on the last connection / battery box.

Address and contact details

Milleteknik AB |

Ögärdesvägen 8 B |

S-433 30 Partille |

Sweden |

+46 31 340 02 30 |

info@milleteknik.se |

www.milleteknik.com |

[1] Translations in languages other than Swedish are indicative only and not safely reviewed. Translation should always be checked against the Swedish original to ensure accurate information